Comprehensive Guide to Acid Resistant Tiles

Acid resistant tiles are specialized flooring and wall solutions designed to withstand harsh chemical environments. They are widely used in industries, laboratories, and food processing units where exposure to corrosive acids and chemicals is frequent. These tiles protect surfaces from corrosion, reduce maintenance costs, and enhance workplace safety. Among the leading providers, Roka Chem is recognized for producing high-quality acid resistant tiles that combine durability, chemical resistance, and aesthetic appeal.

What Are Acid Resistant Tiles?

Acid resistant tiles are engineered to resist chemical corrosion and maintain their integrity even under extreme exposure to acids, alkalis, and other aggressive chemicals. They are typically made from high-grade ceramic, vitrified compounds, or epoxy-coated materials. These tiles are essential for environments where conventional tiles or flooring would degrade rapidly due to chemical attack. Roka Chem is a trusted brand in this segment, offering tiles that meet rigorous industrial standards and provide long-lasting protection.

Composition and Manufacturing of Acid Resistant Tiles

The strength and reliability of acid resistant tiles come from their unique composition. Most acid resistant tiles are manufactured from high-purity clay, quartz, feldspar, and other natural minerals, fired at high temperatures to create a dense and chemically inert surface. Advanced versions include a glass lining or epoxy coating for extra protection against aggressive chemicals.

The manufacturing process involves several steps: selecting raw materials, molding, firing, coating (if applicable), and rigorous quality control. Roka Chem employs state-of-the-art manufacturing techniques to ensure each tile offers exceptional chemical resistance and durability, making it suitable for the most demanding industrial applications.

Types of Acid Resistant Tiles

Acid resistant tiles are available in different types depending on their material and use:

-

Ceramic Acid Resistant Tiles – Made from high-purity clay, these tiles offer moderate chemical resistance and are ideal for laboratories and light industrial areas.

-

Vitrified Acid Resistant Tiles – Featuring a glass-like surface, vitrified tiles are highly resistant to acids and alkalis and are widely used in chemical industries.

-

Epoxy Coated Acid Resistant Tiles – These tiles have an additional epoxy layer for enhanced protection against highly corrosive chemicals and are commonly used in pharmaceutical plants and heavy chemical industries.

Roka Chem provides all these types, ensuring that every industrial or laboratory environment can find a tile solution tailored to its specific needs.

Advantages of Acid Resistant Tiles

Investing in acid resistant tiles offers numerous benefits for industrial and laboratory environments:

-

Chemical Resistance – Acid resistant tiles protect surfaces from corrosive chemicals, preventing damage and ensuring safety.

-

Durability – These tiles withstand heavy machinery, foot traffic, and constant chemical exposure without cracking or deteriorating.

-

Easy Maintenance – Cleaning is straightforward; most chemical stains and residues can be removed without damaging the tiles.

-

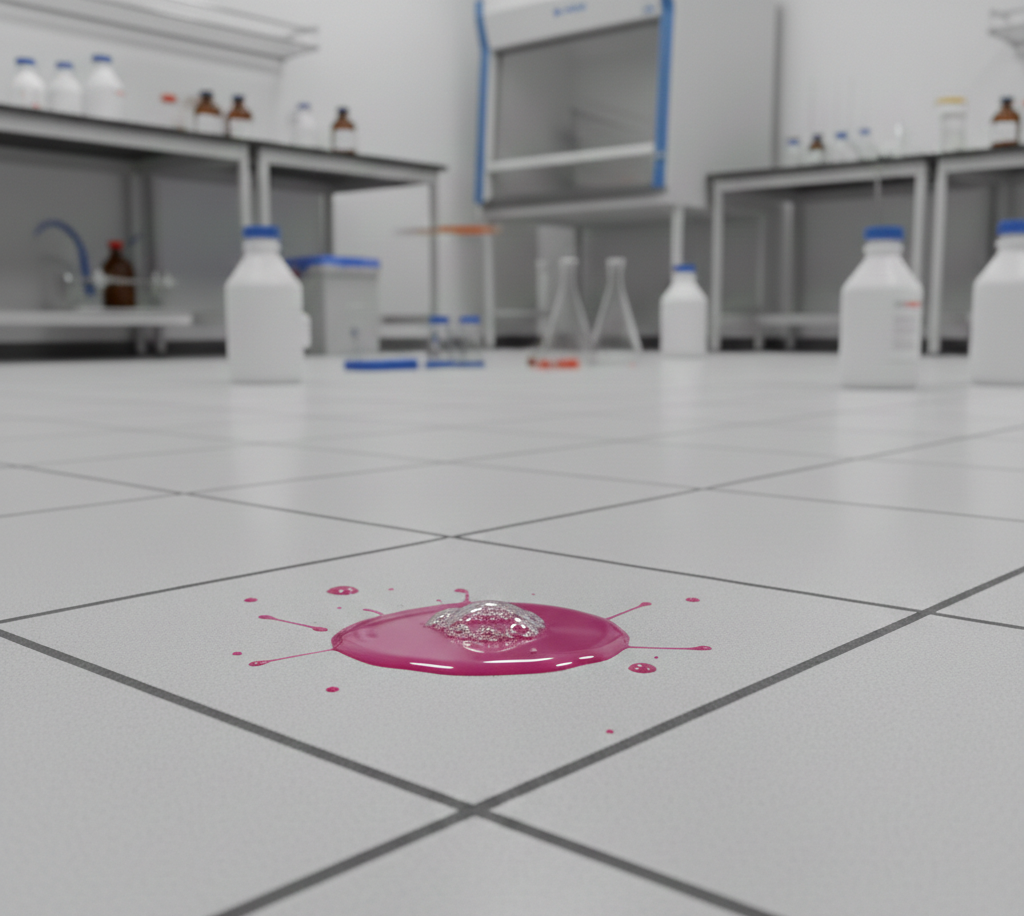

Safety – By preventing surface corrosion, acid resistant tiles reduce the risk of accidents caused by chemical spills.

-

Aesthetic Value – High-quality acid resistant tiles are available in various colors, finishes, and textures, ensuring professional and visually appealing surfaces.

Roka Chem acid resistant tiles are particularly known for combining these benefits, delivering both functional and aesthetic solutions.

Applications of Acid Resistant Tiles

Acid resistant tiles are widely used across multiple industries due to their chemical resistance and durability:

-

Chemical Industries – For floors and walls exposed to acids, alkalis, and other corrosive substances.

-

Pharmaceutical Plants – Ensuring hygienic, chemically resistant surfaces in production and storage areas.

-

Laboratories – Protecting workbenches, floors, and walls from chemical spills and splashes.

-

Food Processing Units – Withstanding acidic cleaning agents and food acids used during production.

-

Industrial Kitchens – Offering resistance against cleaning chemicals and food-related acids for long-lasting surfaces.

By choosing Roka Chem acid resistant tiles, industries ensure surfaces remain protected, safe, and easy to maintain.

Installation Process of Acid Resistant Tiles

Proper installation is critical to maximizing the performance of acid resistant tiles. The standard installation process includes:

-

Surface Preparation – Cleaning and leveling the base surface to ensure strong adhesion.

-

Tile Layout – Planning the layout carefully to minimize cuts and ensure a uniform finish.

-

Adhesive Application – Using chemical-resistant adhesives for secure bonding.

-

Tile Placement – Laying tiles precisely with uniform gaps for grouting.

-

Grouting and Sealing – Applying high-quality, chemical-resistant grout and sealing the surface to prevent penetration by liquids.

Roka Chem provides technical guidance for installation, ensuring that their acid resistant tiles deliver maximum protection and longevity.

Maintenance Tips for Acid Resistant Tiles

While acid resistant tiles are highly durable, proper maintenance ensures their long-term performance:

-

Use neutral cleaning agents to prevent surface degradation.

-

Immediately clean chemical spills to avoid staining or damage.

-

Inspect tiles regularly for cracks or damage and replace if necessary.

-

Avoid harsh mechanical tools that could scratch or compromise the surface.

Roka Chem acid resistant tiles are designed to simplify maintenance, offering high resistance to chemicals and minimizing cleaning effort.

Why Choose Roka Chem Acid Resistant Tiles?

Roka Chem has become a trusted brand in acid resistant tiles for several reasons:

-

Premium Materials – Only the finest raw materials are used to guarantee chemical resistance and durability.

-

Advanced Technology – Cutting-edge manufacturing ensures consistency and high quality.

-

Variety of Options – Ceramic, vitrified, and epoxy-coated tiles available to meet diverse industrial needs.

-

Expert Guidance – Support in product selection, installation, and maintenance ensures optimal results.

Choosing Roka Chem acid resistant tiles is an investment in long-term protection, durability, and professionalism for industrial and laboratory environments.

Conclusion

Acid resistant tiles are indispensable in industries and laboratories that deal with corrosive chemicals. They provide chemical resistance, durability, safety, and aesthetic appeal, making them a smart investment for floors and walls exposed to acids and harsh substances.

With Roka Chem acid resistant tiles, businesses can ensure high-quality, reliable surfaces that stand the test of time, chemical exposure, and heavy usage. Whether ceramic, vitrified, or epoxy-coated, selecting the right acid resistant tile and following proper installation and maintenance practices guarantees maximum benefits and a professional, long-lasting surface solution.

Investing in Roka Chem acid resistant tiles is more than just purchasing flooring; it is a strategic step toward durability, safety, and efficiency in chemical and industrial environments.

- Arte

- Causas

- Artesanía

- Bailar

- Bebidas

- Película

- Fitness

- Alimento

- Juegos

- Jardinería

- Salud

- Hogar

- Literatura

- Musica

- Redes

- Otro

- Fiesta

- Religión

- Compras

- Deportes

- Teatro

- Bienestar