US Epoxy Resin Market by Type, Application & End Use Analysis 2026–2034

United States Epoxy Resin Market Size and Forecast 2026–2034

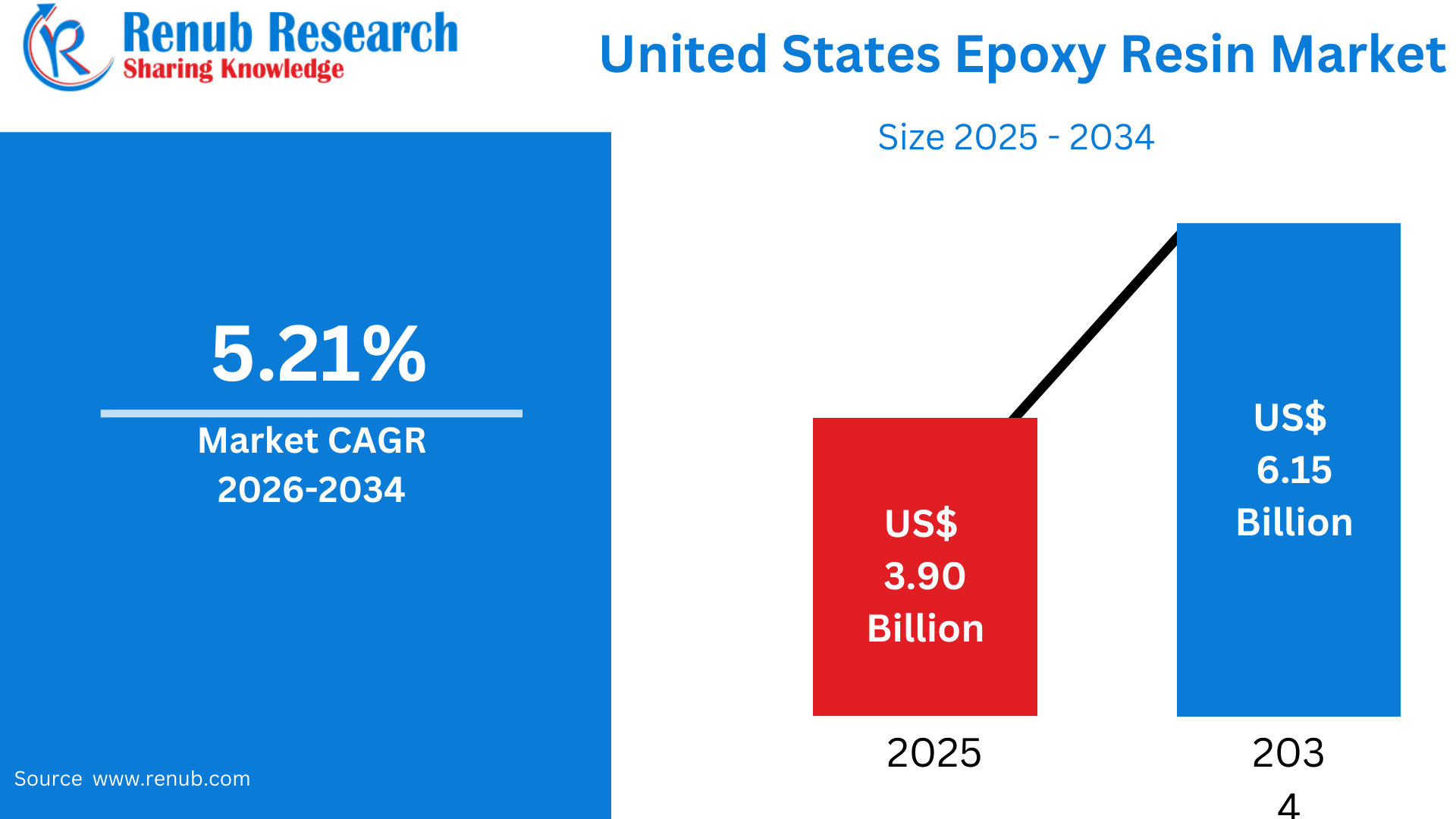

According to Renub Research United States epoxy resin market is positioned for steady expansion over the forecast period, driven by rising demand across construction, automotive, aerospace, electronics, renewable energy, and consumer goods industries. The market is projected to grow from US$ 3.90 billion in 2025 to approximately US$ 6.15 billion by 2034, registering a compound annual growth rate (CAGR) of 5.21% from 2026 to 2034. This growth reflects the increasing adoption of epoxy-based composites, high-performance coatings, and advanced adhesive systems. Continuous infrastructure modernization, lightweight material innovation, and expanding renewable energy installations are reinforcing the long-term outlook for epoxy resins in the United States.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=united-states-epoxy-resin-market-p.php

United States Epoxy Resin Market Outlook

Epoxy resin refers to a versatile group of thermosetting polymers produced through the reaction of epoxide groups with curing agents. Once cured, epoxy resins exhibit exceptional mechanical strength, chemical resistance, thermal stability, and adhesion. These properties make epoxy resins indispensable in applications such as protective coatings, adhesives, electrical encapsulation, laminates, flooring systems, and structural composites.

In the United States, epoxy resins have become a foundational material across industrial and commercial sectors due to their reliability and adaptability. Construction and infrastructure projects rely heavily on epoxy coatings and repair systems for corrosion protection and durability. Automotive and aerospace manufacturers increasingly use epoxy-based composites to reduce weight while maintaining structural strength. In electronics, epoxy resins play a critical role in insulation, encapsulation, and heat management. Additionally, epoxy resins have gained popularity in residential renovation and DIY markets, where they are used for flooring, countertops, artistic applications, and waterproofing solutions.

Growth Drivers in the United States Epoxy Resin Market

Increasing Demand for High-Performance Materials Across Industries

One of the most significant growth drivers for the U.S. epoxy resin market is the rising demand for high-performance materials across multiple industrial sectors. Industries such as construction, automotive, aerospace, marine, and electronics increasingly require materials that combine durability, lightweight characteristics, and resistance to corrosion and chemicals. Epoxy resins meet these requirements effectively, making them a preferred choice for structural bonding, composite manufacturing, and protective coatings.

Infrastructure modernization initiatives, including highway rehabilitation, bridge repair, and industrial facility upgrades, further support epoxy resin demand. In automotive and aerospace manufacturing, epoxy-based composites enable fuel efficiency improvements and enhanced safety through weight reduction. Strategic investments and expansions by chemical manufacturers have also strengthened domestic production capabilities, supporting long-term market stability.

Growth in Construction, Coatings, and Infrastructure Upgrades

The United States continues to invest heavily in commercial construction, public infrastructure, and industrial refurbishment projects. Epoxy resins play a vital role in these developments due to their superior adhesion, durability, and chemical resistance. Epoxy coatings are widely used to protect concrete floors, steel structures, pipelines, and storage tanks from abrasion, corrosion, and environmental stress.

Decorative epoxy flooring has gained popularity in residential and commercial buildings because it offers long service life, low maintenance, and visual appeal. Sustainability trends are also influencing the market, with increasing demand for low-VOC and environmentally compliant epoxy formulations. These factors collectively position epoxy resins as a key material in the evolving U.S. construction and infrastructure landscape.

Expanding Use of Composite Materials in Automotive and Aerospace

The growing adoption of advanced composite materials in the automotive and aerospace sectors continues to drive epoxy resin consumption. Epoxy-based composites provide high strength-to-weight ratios, excellent fatigue resistance, and thermal stability, making them suitable for critical structural applications. In the automotive industry, epoxy resins are essential in electric vehicle components such as battery encapsulation, insulation, and thermal management systems.

In aerospace manufacturing, epoxy composites are widely used in fuselages, wings, interior panels, and structural supports. These materials help improve fuel efficiency, increase payload capacity, and enhance durability. Continuous innovation in epoxy resin systems supports the development of next-generation transportation technologies in the United States.

Challenges in the United States Epoxy Resin Market

Volatility in Raw Material Prices and Supply Chain Pressures

A major challenge facing the U.S. epoxy resin market is the volatility of raw material prices, particularly petroleum-based feedstocks such as bisphenol-A and epichlorohydrin. Fluctuations in crude oil prices, geopolitical uncertainties, and refinery capacity constraints can significantly impact production costs. Supply chain disruptions affecting curing agents, additives, and specialty chemicals further complicate pricing strategies and profit margins.

Small and medium-sized manufacturers are especially vulnerable due to limited sourcing flexibility. These factors can hinder long-term planning and create uncertainty within the market.

Environmental Concerns and Regulatory Compliance

Environmental sustainability has become an increasingly important issue for the epoxy resin industry. Concerns related to VOC emissions, toxic by-products, and the environmental impact of synthetic raw materials have prompted stricter regulatory oversight. Compliance with environmental and workplace safety regulations often requires significant investment in cleaner production technologies and product reformulation.

While bio-based and environmentally friendly epoxy alternatives are gaining attention, they often involve higher costs or performance limitations. Balancing regulatory compliance, sustainability goals, and product performance remains a key challenge for market participants.

United States DGBEA Epoxy Resin Market

DGBEA epoxy resins represent the largest segment of the U.S. epoxy resin market due to their excellent balance of mechanical strength, chemical resistance, and versatility. These resins are widely used in coatings, adhesives, composites, and electrical encapsulation systems. Their compatibility with a wide range of curing agents makes them suitable for applications in construction flooring, marine coatings, automotive components, and industrial maintenance.

DGBEA-based systems provide long-term durability and corrosion protection, making them essential for infrastructure repair and industrial applications. Their thermal stability and moisture resistance also support widespread use in electronics and electrical insulation.

United States Aliphatic Epoxy Resin Market

The U.S. aliphatic epoxy resin market is expanding steadily, driven by demand for UV-resistant and weather-stable materials. Aliphatic epoxy systems offer superior color retention, gloss stability, and resistance to yellowing, making them ideal for outdoor and decorative applications. These resins are commonly used in protective topcoats, clear coatings, automotive refinishing, marine exteriors, and architectural surfaces.

Although aliphatic epoxy resins are typically more expensive than aromatic alternatives, their performance advantages make them valuable in premium applications requiring long-term durability and aesthetic stability.

United States Solid Epoxy Resin Market

Solid epoxy resins are widely used in the United States due to their stability, long shelf life, and suitability for powder coatings and high-durability applications. These resins are commonly applied in corrosion-resistant coatings for appliances, metal components, pipelines, and automotive parts. Solid epoxy-based powder coatings provide excellent abrasion resistance, adhesion, and chemical protection.

In electrical and electronics applications, solid epoxy resins are used in laminates, insulation materials, and circuit boards. The growing preference for solvent-free and environmentally friendly coating technologies continues to support demand for solid epoxy systems.

United States Epoxy Resin Paints and Coatings Market

Epoxy resin paints and coatings account for a significant share of the U.S. market due to their unmatched durability and protective performance. These coatings are used extensively on steel structures, concrete floors, machinery, pipelines, marine vessels, and storage tanks. Epoxy flooring systems are favored in industrial and commercial facilities for their resistance to wear, chemicals, and impact.

Infrastructure modernization projects, including bridge rehabilitation and water treatment facility upgrades, continue to drive demand. Advances in low-VOC and hybrid epoxy technologies further enhance the importance of this segment.

United States Epoxy Resin Electronic Encapsulation Market

Epoxy resins play a critical role in the electronic encapsulation market by protecting sensitive components from moisture, vibration, dust, and thermal stress. Epoxy-based potting compounds are widely used in transformers, semiconductors, sensors, LED systems, automotive electronics, and renewable energy inverters.

The rapid growth of electric vehicles and domestic electronics manufacturing has increased demand for high-purity epoxy encapsulants. Their dielectric strength, thermal conductivity, and long-term reliability make epoxy resins essential for modern electronic systems.

United States Epoxy Resin Building and Construction Market

The building and construction sector is a major consumer of epoxy resins in the United States. Epoxy flooring systems are extensively installed in industrial plants, hospitals, commercial buildings, and public facilities due to their seamless finish and ease of maintenance. Epoxy adhesives are used for structural bonding of concrete, steel, and composite materials.

Epoxy-based repair and waterproofing systems are critical for extending the lifespan of aging infrastructure. Decorative epoxy applications have also gained popularity in residential construction, supporting sustained market growth.

United States Epoxy Resin Consumer Goods Market

Epoxy resin usage in U.S. consumer goods has grown rapidly, particularly in DIY crafts, home décor, furniture, and artistic applications. Consumers use epoxy for river tables, jewelry, resin art, protective coatings, and customized household items. Social media platforms and online tutorials have increased awareness and adoption of DIY epoxy kits.

Home renovation trends, including countertop refinishing and garage flooring upgrades, further contribute to market expansion. The versatility and aesthetic appeal of epoxy resins ensure continued demand in this segment.

United States Epoxy Resin Aerospace Market

The aerospace sector is one of the most significant consumers of epoxy resins in the United States. Epoxy-based composites are essential for manufacturing lightweight aircraft structures, including fuselages, wings, and interior components. Epoxy adhesives provide strong bonding between metals and composite materials, reducing the need for mechanical fasteners.

Growing investment in commercial aviation, defense aircraft, and space exploration supports ongoing demand for advanced epoxy resin systems. These materials play a key role in improving fuel efficiency, safety, and performance.

Regional Analysis of the United States Epoxy Resin Market

California leads the U.S. epoxy resin market due to strong construction activity, electronics manufacturing, and sustainability-driven demand for low-VOC formulations. New York’s market is supported by continuous infrastructure maintenance, commercial construction, and industrial flooring applications. Washington benefits from aerospace manufacturing, maritime activities, and advanced electronics production. Arizona’s fast-growing construction sector drives demand for epoxy coatings and flooring systems capable of withstanding extreme climate conditions.

Market Segmentation Overview

Type

DGBEA, DGBEF, Novolac, Aliphatic, Glycidylamine, and others.

Form

Solid, Liquid, and Solution.

Application

Paints and coatings, adhesives and sealants, composites, electronic encapsulation, and others.

End Use

Building and construction, transportation, general industrial, consumer goods, wind energy, aerospace, and marine.

Top States

California, Texas, New York, Florida, Illinois, Pennsylvania, Ohio, Georgia, New Jersey, Washington, and others.

Competitive Landscape and Company Analysis

The U.S. epoxy resin market is moderately consolidated, with key players focusing on capacity expansion, innovation, and sustainability. Major companies operating in the market include Aditya Birla Group Chemicals, Atul Ltd., BASF SE, Chang Chun Group, Covestro AG, Daicel Corporation, DuPont de Nemours Inc., Hexion Holdings Corporation, Kukdo Chemicals Co. Ltd., and Olin Corporation. These companies are evaluated based on overviews, key leadership, recent developments, SWOT analysis, revenue performance, and strategic positioning.

- Arte

- Causas

- Artesanía

- Bailar

- Bebidas

- Película

- Fitness

- Alimento

- Juegos

- Jardinería

- Salud

- Hogar

- Literatura

- Musica

- Redes

- Otro

- Fiesta

- Religión

- Compras

- Deportes

- Teatro

- Bienestar